BENEFIT TO RETAILERS

30%+ per loaf margins

Incredible in-store aroma

Unique in-store experience

Lowers waste and carbon use

Hot loaves for customers all day long

Clean label product

30%+ per loaf margins

Incredible in-store aroma

Unique in-store experience

Lowers waste and carbon use

Hot loaves for customers all day long

Clean label product

| Fee | Description |

|---|---|

| $3,000-$7,000 | Installation Fee (dependent on location) |

| $1,000 per month | Lease Fee |

| $2.15-$2.50 | Per Loaf Fee (depends on variety) |

At $4.99 per loaf, only 22 loaves per day covers the lease payments. At 45 loaves per day, margins grow above 30% per loaf. Installation fees are paid back in 2-3 months. With a low cost of entry, the BreadBot system is accretive very quickly.

The first BreadBot was specifically designed for grocery stores. It allows customers to know exactly where, when, and how, their bread was made. Freshness and transparency in food production are our aim.

After rigorous in-store testing, we’ve found the optimal production for a typical grocery store to be 10 loaves per hour. This implies a total daily capacity of 200 loaves—far beyond the needs of most grocers—while still reserving an hour for cleaning.

Because of the autostart option, stores can schedule the BreadBot to start baking hours before the store opens. This allows for a head start — if necessary — to meet daily production demands.

The BreadBot is constantly adjusting production throughout the day to achieve the optimal bread inventory. Smart production determines exactly how many loaves of each variety are needed in any given moment and immediately adds them to the queue.

The BreadBot will ask for help throughout the day when necessary. It might request: "Please empty the cabinet of bread", "Please add more mix", or "Finished baking today". This communication allows store staff to focus on their other tasks and only tend to the BreadBot when truly necessary.

After baking for the day, the BreadBot will immediately start its auto-cleaning cycle to clean out the mixing pot. After that’s finished a store employee will finish cleaning by wiping down surfaces and refilling ingredients for the next day.

All measurements are unique by recipe and constantly monitored by the system. From the water temperature and mixer speed, to the proofer humidity and loaf height, sensors are tracking over 40 unique metrics on each loaf produced.

Once dry mix is added to the hopper the process is fully automated. The BreadBot sends a message to an employee when the more ingredients are needed or loaves need to be emptied from the cooling cabinet.

Each BreadBot has a touchscreen with a visual display that enables store staff to monitor every aspect of the bakery. Employees can monitor important bakery functions such as ingredient levels, oven temperature, loaf age, and overall bakery status.

Each store has direct access to the Wilkinson Baking monitoring and support team for any issues that may arise. If an issue requires an onsite visit from a technician, Wilkinson Baking will dispatch, support and manage that visit.

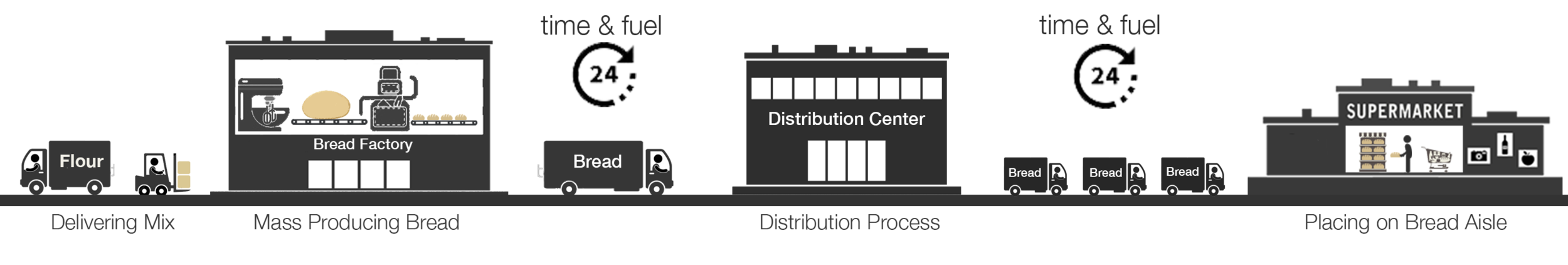

The old model mass produces bread in a large, centralized factory, ships the bread to distribution centers, and then ships that bread to stores. This model requires tens of thousands of trucks on the road and leaves the customer with less than a fresh loaf.

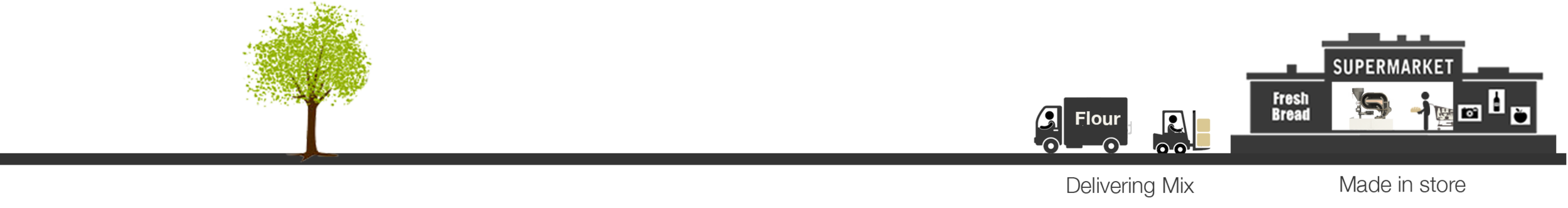

The new model distributes the bread factory to the store and bakes locally. It eliminates the need for a truck to deliver bread and allows the customer to take fresh bread minutes after it's been baked. A better loaf and better for our earth.

less wasted bread

baking for daily demand

more efficient shipping

shipping dry mix instead of loaves of bread

Fresh

baking on site vs in factories

“Imagine a world where firms automate manufacturing close to target markets

instead of shipping long distances from cheap production centers.”

— Worth Wray, Economist